|

|

Post by USCGME2 on Feb 21, 2015 6:34:43 GMT -7

@cwi or Crash - Can one, or both, of you guys (or anyone else for that matter)post some stuff on the different steels used in blades and maybe give a Steel 101 "crash" course for a third grader in the room like me? ie) What is T10 tool steel vs the four digit spring steels vs L6, powder steels, and hammered cable etc? through hardening and differential hardening? How would these compare to say, Crash blades hardening and steel types? All I really know at this point is that the old blades were folded over and over to make them more homogenous which is not a problem with modern steels. Actually, it seems that folding modern steel actually weakens it? Anyway, any info on this is most welcome. Read more: survivalbunker.proboards.com/thread/9585/katanas?page=2#ixzz3SNzf6mtC |

|

|

|

Post by Cwi555 on Feb 21, 2015 6:59:25 GMT -7

Angelhelp once ask that question of me. In her case it was for a student interested in metallurgy. It turned out to be a very difficult task due to the breadth of underlying information/science that supports each of the answers.

After considering the problem, it's my opinion it should be tackled on a case by case basis. The subject is a very large elephant so it has to be eaten a bite at a time.

|

|

|

|

Post by USCGME2 on Feb 21, 2015 7:23:11 GMT -7

Angelhelp once ask that question of me. In her case it was for a student interested in metallurgy. It turned out to be a very difficult task due to the breadth of underlying information/science that supports each of the answers. After considering the problem, it's my opinion it should be tackled on a case by case basis. The subject is a very large elephant so it has to be eaten a bite at a time. Good point. - Lets start with four digit "spring" steels. Just a brief over view for general understanding will suffice. Just want to know what is in most blade offerings. Maybe we could make this one a sticky and add to it over time??? |

|

|

|

Post by Cwi555 on Feb 21, 2015 7:26:19 GMT -7

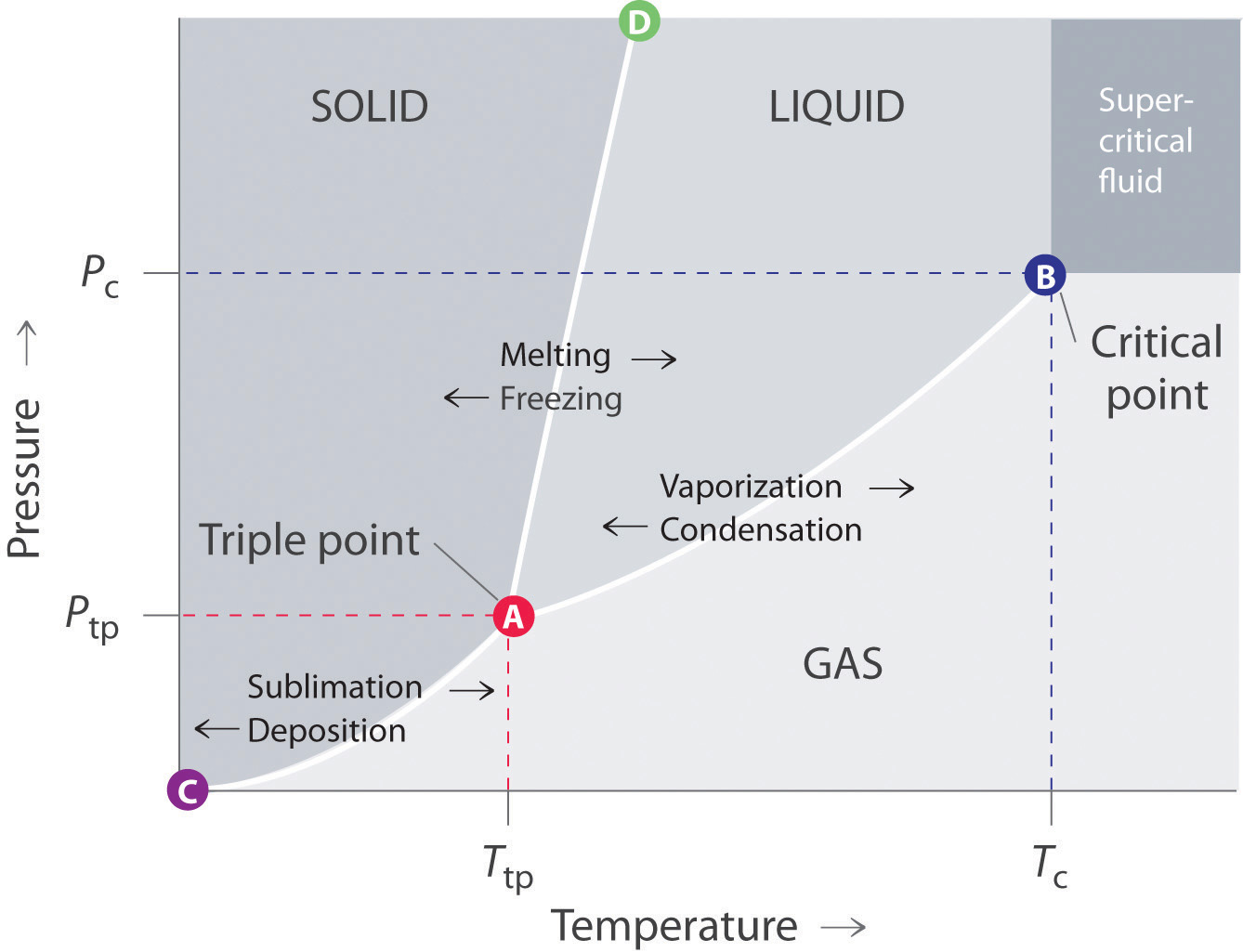

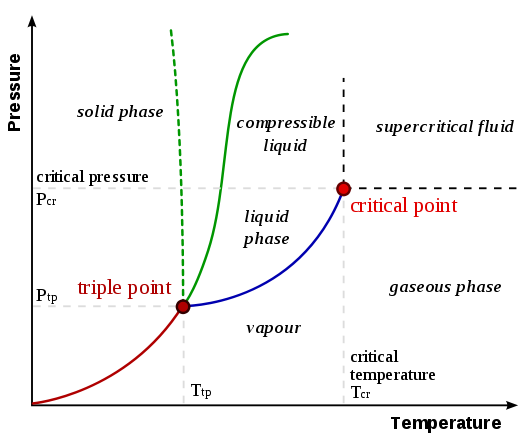

To get you started, a few terms to look up. Carbon content Elasticity Tensile strength Stress strain diagram The various forms of hardness test (brinnel, knoop, mohs, rockwell, vickers, shore etc.  Common crystal structures  Those are the most common btw, there are several dozen depending on definition. Phase diagrams   The various phase specifics  Austenite, perlite, banite, etc. matweb.com/That site allows you to search specific metals. Anyone can get their mind around the subject, but it takes time and if there is a short circuit way of getting there, I don't know what it is. |

|

|

|

Post by Cwi555 on Feb 21, 2015 7:51:51 GMT -7

Angelhelp once ask that question of me. In her case it was for a student interested in metallurgy. It turned out to be a very difficult task due to the breadth of underlying information/science that supports each of the answers. After considering the problem, it's my opinion it should be tackled on a case by case basis. The subject is a very large elephant so it has to be eaten a bite at a time. Good point. - Lets start with four digit "spring" steels. Just a brief over view for general understanding will suffice. Just want to know what is in most blade offerings. Maybe we could make this one a sticky and add to it over time??? Spring steels are not all for digit. The stainless variants come in 300 series and up. Carbon, nickel, chromium content are the primary difference. Some grades cannot be hardened, while others can be made brittle if not treated correctly. They have a very high modulus of elasticity, but a very low shear modulus. matweb.com/search/DataSheet.aspx?MatGUID=4bcaab41d4eb43b3824d9de31c2c6849&ckck=1To use a generic steel c1080 for a clearer example. Carbon-grade steel begins with the letter C and the number 1. The second number is based on the extra elements (such as sulfur) added to the steel. So if the second digit is 2, two elements were added. Since 1080 first two digits are 1 and 0, it’s iron. The last two digits are it's carbon content. In this example it means the steel is .8% carbon. American Iron and Steel Institute (AISI) designates .12%-2% carbon content as the range of 'carbon steel'. |

|

|

|

Post by USCGME2 on Feb 21, 2015 8:47:45 GMT -7

That last paragraph was really helpful. So a knife blade of 1045 will have less carbon than 1060, soooo - the 1045 "should" be more elastic but, not hold an edge as well as the 1060. Am I tracking so far? I see many knives/swords with 10xx Spring steel. Is spring steel a generic genus of steels or a specific blend? By spring, do they mean coiled springs, leaf, bar or all the above?

Keep it coming, Im really enjoying this discussion/ lesson. I do realize its a DEEP topic so shallow wading is ok for now. Thanks CWI. Crash, dont hesitate to jump in, you got a lot of practical knowledge too (as well as others!)

|

|

|

|

Post by thywar on Feb 21, 2015 9:36:05 GMT -7

My steel questions about knives are 1) does it cut and 2) how often do I have to sharpen it to make it cut?

I love being a simple person. ;-)

|

|

|

|

Post by Cwi555 on Feb 21, 2015 11:25:28 GMT -7

That last paragraph was really helpful. So a knife blade of 1045 will have less carbon than 1060, soooo - the 1045 "should" be more elastic but, not hold an edge as well as the 1060. Am I tracking so far? I see many knives/swords with 10xx Spring steel. Is spring steel a generic genus of steels or a specific blend? By spring, do they mean coiled springs, leaf, bar or all the above? Keep it coming, Im really enjoying this discussion/ lesson. I do realize its a DEEP topic so shallow wading is ok for now. Thanks CWI. Crash, dont hesitate to jump in, you got a lot of practical knowledge too (as well as others!) I really don't like the term 'spring steel' because it's misleading. Carbon content plays a large role when it comes to a steel that can be hardened, not so much regarding any spring like qualities. Specific solidifation phases and ductile qualities do. The generic term spring steel relates to its ductility aka modulus of elasticity. The simple explanation is that when it is bent, it will return to its original a shape without permanent deformation. That gets to a stress strain curve, and specific directional quality as 'spring steels' have strong tensile properties, but weak shear qualities. Consider bending wood against the grain vs with the grain for a similar effect. |

|

|

|

Post by USCGME2 on Feb 21, 2015 14:11:15 GMT -7

Thanks, that does explain alot. Man you weren't kidding, there is an enormous amount of knowledge out there about steel! I had no idea such a common thing had such uncommon complexity. Ive just been doing a little online self study today and I learned a lot just about common terms like pig iron, wrought iron, woot, damascus, stainless etc. modern steel is actually quite amazing. Maybe this is a simple question but, I've heard you say that Crash's saw blade knives (of which I own a couple myself  ) are of really great steel. I know they are but, you elaborate a bit on why? |

|

|

|

Post by Cwi555 on Feb 21, 2015 17:34:23 GMT -7

Thanks, that does explain alot. Man you weren't kidding, there is an enormous amount of knowledge out there about steel! I had no idea such a common thing had such uncommon complexity. Ive just been doing a little online self study today and I learned a lot just about common terms like pig iron, wrought iron, woot, damascus, stainless etc. modern steel is actually quite amazing. Maybe this is a simple question but, I've heard you say that Crash's saw blade knives (of which I own a couple myself  ) are of really great steel. I know they are but, you elaborate a bit on why? He has a good eye for heat treat. The list of people who can shape a blade is a very long one, the list of people who have a good eye/feel for sound metal and heat treat is inversely squared of the former number. There just isn't that many out there with the innate talent he has. Added to this is the judicious use of materials. Those pits when smoothed out have a strong side effect. Shear stresses transmit throughout the blade. Some people focus on just the edge which is a mistake. Those pits add surface area to share the load. One of the ways a metallurgical lab performs failure analysis of metals is microscopic imaging of slip bands.  www.nde-ed.org/EducationResources/CommunityCollege/Materials/Structure/deformation.htm www.nde-ed.org/EducationResources/CommunityCollege/Materials/Structure/deformation.htmWhen a surface such as his blades have been properly treated they transmit those stresses without interuption. That includes surface stresses. A surface defect is the worst case scenario as it gives those stresses a point of focus. Doesn't have to be a defect either, a sharp corner will do it to. That gets to his overall design. If you have one, you will note the smooth transitions from one plane to the other. Added to this are the ones he's made with the light pitting. For those the edges of the pitting are smoothed out with no point at which the stress may concentrate. Without those stress risers, slip bands have a hard time forming because the intermetallic grain structure was A) properly relieved after cold working an B) properly shaped to avoid such to begin with. I don't have the first one I ever got from him as it was sacrificed to my brand of 'testing' which means it gets destroyed. I've purchased several since because of those results. I have a lot of blades, but the one I carry in my primary BOB, the one in my truck, the one my wife carries, all are his work. |

|

|

|

Post by Cwi555 on Feb 21, 2015 17:38:20 GMT -7

One more thing. Not all of his blades use that pit style. However they are of equal quality.

|

|

|

|

Post by crashdive123 on Feb 22, 2015 5:25:15 GMT -7

I'm probably not a big help on this subject. I use steels that have proven that they can be good knives with a proper heat treatment.

|

|

|

|

Post by Ceorlmann on Feb 22, 2015 7:33:57 GMT -7

I'm probably not a big help on this subject. I use steels that have proven that they can be good knives with a proper heat treatment. But that's something you have that most of us on the forum don't. You have the experience. Your knowledge may not necessarily be from a vast amount of scientific knowledge such as cwi has, but there's a reason why experience weighs a lot, in some cases more than academic knowledge, when working a job. You have the experience of knowing which steels worked well while others didn't. I'm not music professor material (except for being able to talk for a long time), but from my musical experience on performances I'm not going to play some number again if the audience is the same and they didn't receive it well. I'm also not going to perform in a certain location again where we have more people in the band itself than in the audience (this actually happened in my last Marine band in 29 Palms when we also had members of the Prez Own Marine Band performing with us; worst concert ever as far as audiences go). |

|

|

|

Post by Ceorlmann on Feb 22, 2015 7:36:34 GMT -7

One more thing. Not all of his blades use that pit style. However they are of equal quality. I've been learning that about his blades while using them myself. They've actually taken the space my kabars and other knives have occupied in my BOB and EDC bag. |

|

|

|

Post by Redneckidokie on Feb 22, 2015 22:10:43 GMT -7

If you just want to gleen common knife related info join Blade forums.

They are some Serious knife makers. Live it, breathe it.

Wound a dab too tight for my tastes, but temper what you read there with CWI and Crash.

You seem to have a dose of the fever? Turning toward the dark side. The secret of steel. LoL

|

|