|

|

Post by woodyz on Oct 16, 2012 16:34:55 GMT -7

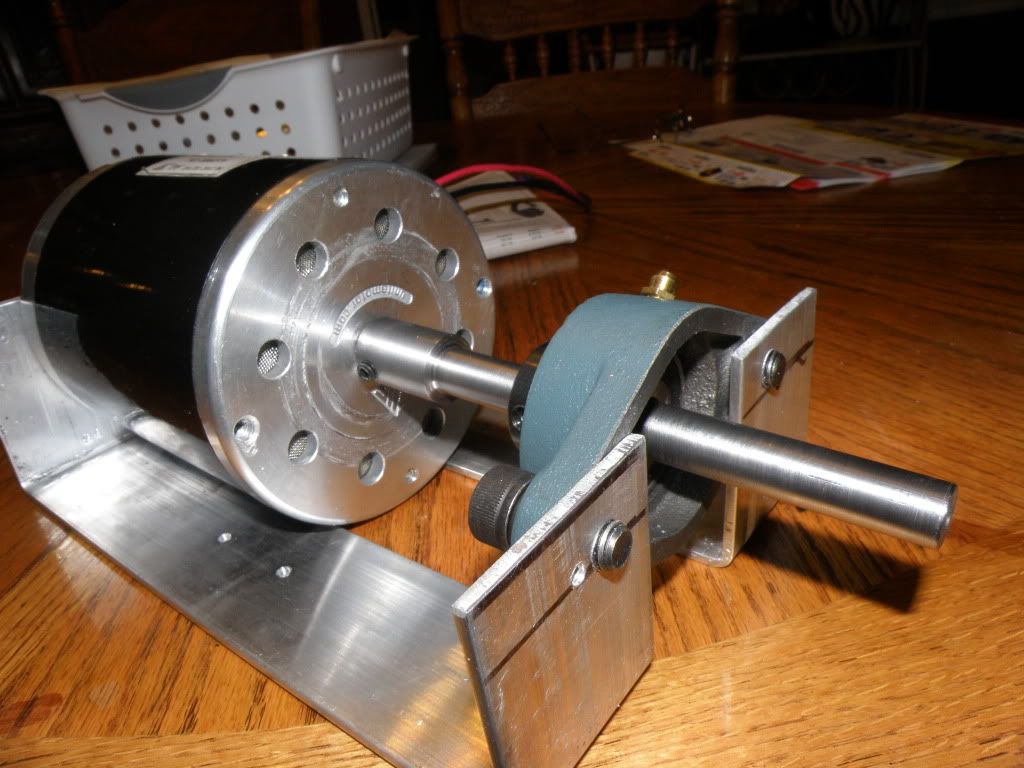

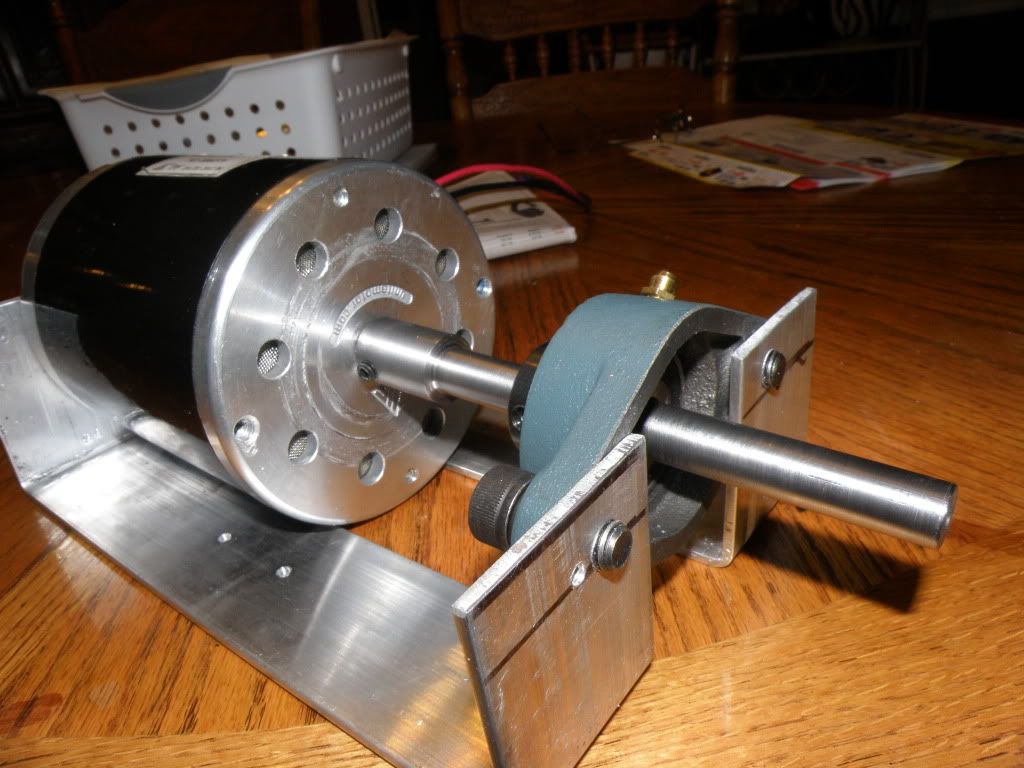

In my opinion, being able to charge deep cycle batteries will become more important the long SHTF lasts. Solar comes easy now. $65 buys a solar panal that keeps two deep cycle 12 volt batteries charged in the boat and the RV. One charges the battery that runs the well pump. So we have become comfortable about being able to charge batteries with a small solar panel. Understanding its just a matter of increasing the size and/or number to increase the out put. Now we are working on building our own panels from what is available. So now we have moved to testing out wind power to charge batteries. Using what we had laying around we built this wind turbine for $0.00, it puts out 36 volts or 18 amps when at full capacity. I don't expect to reach full capacity very often in South Carolina. At least not where we live, maybe off the coast or off a lake, but not here. All I want to do is proof we can charge batteries with the wind. A resonabaily accepted fact, but I want to do it with things people might have on hand or be able to find without much trouble. So today was its first test run. We recharged a drained 12 volt car battery in about six hours. We will do that a few more times and then hook a 12 light up and take power out, while the wind mill puts power in. I am not expecting the input to be equal or greater than the output right now, just testing it out. Things we learned in running it today. The plexiglass vanes may flex too much, taking some of the energy away from the rotation. Either they need to be shorter or stiffened. So we decided to try adding a small aluminum channel to one edge of each. I don't like the extra weight but we will see. Also the tail doesn't need to be as long as it is. It does act as a vane to turn the assembly into the wind, but it is pulling down the one side and causing friction on the rotory device. Which brings me to the rotory device, we intend to use the bearing assembly from a fan, but didn't have one on hand so we used a kitchen carrosel assembly. Metal, but a little too big around, causing additional effort to keep it moving 360 with the wind. And the bearings are just small ball bearings in a circle housing. It needs to be smaller with bigger bearings because as it is they will wear out pertty fast. Which we intend to let happen, so we will know how long. We lubricated the assembly with wd40, which will also be a problem as it breaks down. I have some powered alumium to use for the next version. So here are a couple of pictures. Let me know what you think.   |

|

|

|

Post by blacksmith on Oct 16, 2012 17:30:09 GMT -7

wow that is not bad and is working that is great would love to see more as you get it going

|

|

|

|

Post by thywar on Oct 16, 2012 17:38:42 GMT -7

I'm impressed.. that's very cool..

|

|

|

|

Post by urbanprep on Oct 16, 2012 17:38:45 GMT -7

looks great. makes me want to get my similar project out of storage ...

|

|

|

|

Post by alex on Oct 16, 2012 17:55:23 GMT -7

More details on the generator and such...what kind of genny is it and where is one obtainable?

|

|

|

|

Post by garret on Oct 16, 2012 22:56:13 GMT -7

excellent work there woodzy

most of the plans i have seen make the vanes out of schedule 40 or even 80 pvc pipe, would this be a more viable option than perspex blades?

|

|

|

|

Post by missj on Oct 16, 2012 23:31:16 GMT -7

I'm just thoroughly impressed!

People like you who can think to make things like this out of basically "scrap" or "junk" material just amaze me...

hope I am not prying, but do you have a touch of aspergers or autistic spectrum? I ask with respect and love because my husband, nephew and a good friend from gradeschool all have a "touch" of it...not enough to interfere with life...but enough to be able to look at ordinary items like this and imagine "power generation".

I simply don't have that "thing" in my brain...I can look at fabric or old rags and imagine a dress or overalls...I can look at pallets and scrap lumber and imagine a chicken coop...but I cannot look at household items and imagine mechanical devices...I have no mind for that kind of thing and I really admire those that do....

|

|

|

|

Post by angelhelp on Oct 17, 2012 7:04:39 GMT -7

I think it's more from having been allowed to (or encouraged to) "fool around with" different kinds of materials during childhood, or having been blessed to watch someone older and competent as that person improvised. I know I have the creativity but I lack any practical experience. As a child, I could "make anything" out of construction paper; as an adult, my only progress was in learning to sew. I've never taken anything apart though, and reassembled it differently, not even clothing. My electrical knowledge deficits are even worse, so while I might come up with something resembling a fan or a pinwheel that would move in the wind, I wouldn't have the slightest idea how to use that motion to generate electricity. It's the same with a water wheel for me; how to harvest the energy is a complete mystery even though I fully understand the notion of something in nature turning a wheel and generating mechanical energy. I know wheels/gears can turn others, but I don't know where to begin to make something usable out of it. I've no doubt that I can learn; improvisation is easy when I know my materials, but I sure feel like I've missed out on a lifetime of valuable experiences.

|

|

|

|

Post by thywar on Oct 17, 2012 7:14:18 GMT -7

I completely agree with MissJ and Angelhelp.. I'm creative but to actually figure out and then take those items and assemble them into a productive piece of equipment... not going to happen. I was astounded that I passed the FAST (Flight Aptitude Selection Test) test. I've never seen so many gears and pulleys in one book in my life.. and then to have to figure out which way they're turning.. lol.. only to be denied for hearing loss.

|

|

|

|

Post by tjwilhelm on Oct 17, 2012 7:32:37 GMT -7

Very cool!!! I love seeing this kind of active, hands-on projects!!! As you continue your development of this project, you'll eventually run into the need to prevent over-charging the battery; and, to prevent the turbine from over-speed-spinning in high winds that might destroy it. A great resource for home-brew wind machine design and construction was written by Dan Bartman and Dan Fink. Their designs are based on the pioneering work of Hugh Piggot -- the father of small wind here in America. If you're interested, their book is available on Amazon, and they have two very interesting and informative web sites: otherpower.com/www.buckville.com/drupal/www.amazon.com/Homebrew-Wind-Power-Dan-Bartmann/dp/0981920101These guys are the real deal. They teach a workshop on how to build a wind generator from scratch...totally from scratch...including winding the coils for the generator. There may be info in their book you might find useful as you go forward. Also, if anyone is interested in home-brew wind, if you get a chance to take one of their workshops, it's probably well worth the cost and effort. Keep up the good work!!! |

|

|

|

Post by marc on Oct 17, 2012 10:23:37 GMT -7

From a battery guy's perspective: The charge controller sitting between the generator and the batteries, is the cotter pin of the system.

I very, very rarely see batteries "worn out" from excessive cycling, but I see hundreds that are destroyed by improper charging, mostly undercharging. A charge controller not doing its job properly can quickly destroy the best batteries in the world - and I see it constantly.

Conversely, I have load tested batteries still at 80% capacity after 14 years in service. The difference is proper training of the user and a great charge controller.

|

|

|

|

Post by woodyz on Oct 17, 2012 11:50:03 GMT -7

Answering from the bottom up we do have a charge connector in the line so the batteries can't over charge. Also have a stop switch in line and the 4x4 tower is mounted with two pins so we can pull either one and lower the whole assembly. I am not expecting any of this first run to hold up to use or to power anything. My number one goal here was to proof to our group they could take the basic concepts and make it work with out needing to buy a lot of expensive equipment. Our blades on this are a weakness, but we had an old shower door we could cut them from, they attach to the hub where fan blades attach, giving us some offset and a bit of angle to each. They are not sandwiched but held by wood screws. It will not hold very long or in very much wind. They should be sandwiched and bolted through. I guess my ability to "see" an assembly is from my engineering background, structural, mechanical and architectural. My weakest point is electrical, but my son is an electrical engineer and works in mechanical maintainence, so togeather we can pretty well see something by discussing it. As far as making parts out of off the shelf items. That started with my Grandfather while I was growing up. I would follow him around at a hardware store or what ever looking at how things for sale were put to geather, how they worked. Then going into his shop or an estate auction or the same hardware store and buying or salvaging things that would perform the same task, just not built for that specific application. He once used a piece of leather from a mule ploughing line to make a bearing in a motor. Just so he could finish a job before needing to go to town and buy the bearing. For the rest of my life I have remembered that and always believe there is a possible fix or solution to a problem "outside the box" Now I get my exercise walking around hardware stores and looking at not just the things already built but the odds and ends and parts they have, trying to imagine how it could be used in other ways. Its always cheaper to find something off the shelf and modify it to fit a specific task. Plus it keeps my mind working. We did not invent anything the designs and kits for these are all over the place, so we weren't starting from scratch. We took the basic design and talked about what might work and how for about a week. Then we walked around looking for our idea pieces at the hardware store. Then we looked for those parts or their equal in our garages, sheds, barns and storage buildings. Again from my time spent with my Grandfather I don't throw much away. I always figure I can find a use for it later. Ofcourse the problem becomes finding it later.  Also remember, we didn't intend this become our power source or that it would be used for any length of time. It is our first run, a test of the concept. After this wears out and we "learn" more about what it is doing then we will spend money on parts and pieces with out put and durability in mind. But if you had to charge some batteries and all you had was a garage full of junk, its good to know it can be accomplished. I really don't know what the alternator is from. We had three in the garage so we picked the one with the largest output capacity. If my son knows I will include the info in a later post. Never give up, never give in, never quit. If you quit you die. mod = corrected some spelling |

|

|

|

Post by woodyz on Oct 18, 2012 14:05:33 GMT -7

More on the visualizing aspect of what could be used and how. We had help in understanding what the system had to have by studying our RV. An RV runs on electric 120, batteries 12V or generator. How it all works together was right there in plain sight, as were the controls to switch from one mode of power to another.

My son, being electrical inclined, he started taking his TV, stereo, etc apart to see how they worked a eight years old, he was installing sound systems into high school kids cars at ten. So he had it straight in his mind how it was going to work.

But I don’t do electric so I needed to look a diagrams and read about what each part was supposed to do and how. Generally if I can read it, I can do it.

So first we added four solar panels to the RV. It had a roll out type canopy, so we put the panels on the hinge and they fold down against the body. When they are up they collect energy and work as a canopy. Not as efficient as they could be if mounted to take advantage of the angle of the sun, but still enough to keep the batteries charged.

Doing that project and then the solar panel for the water pump helped us understand the mechanics of getting the energy into and out of the batteries without over charging etc.

So what was left was the angles and length of the blades, their size and how to off set them. How long to make the tail and how big to make the vane and how to do it using junk laying around.

The hardest thing to find a substitute for was the yaw bearings which allow the whole thing to turn 360 and catch the best wind. I think the bearing assembly from a fan would work, but we had already used our junk one for the blades.

So as I said we ended up using one of those spice carrousels that turn 360 to offer different spices etc. But although it works, it isn’t going to be big enough to last for constant turning.

On the issue of the blades I think we will use a third cut from a 6” PVC. I think the cup it offers and the rigidness will be an advantage. Although I don’t have it exactly straight in my mind on how to mount them to the hub. I am thinking to achieve the off sit for each blade we will mount one to one side, one to the middle and one to the opposite edge of the blades which will make each one capture a little different wind movement.

Also I am thinking we will use the sprocket pieces from a bicycle as the hubs. It will be lighter and give more options for bolting, they all ready have the bearing we just have to increase or reduce the connection to the alternator.

One thing for anyone considering it, you can’t just use a car alternator, the bearings just aren’t big enough, you need to find one with over sized bearings. Or just build one, its just magnets and winding and bearings, or maybe use a heavy duty car alternator and rebuild the front end with bigger bearings. I’ll post more on that as we get into our rebuild.

|

|

|

|

Post by woodyz on Oct 18, 2012 14:09:31 GMT -7

I wanted to say before I forgot, on building your own solar panels I think I am going to have to agree with what I read that says it isn't worth the extra effort.

I do think it is a good educational exercise in how they are made, and knowing how to build one may become more impotant and more worth while when you can not buy one. But for now, I say just buy them.

|

|

|

|

Post by woodyz on Nov 1, 2012 16:21:16 GMT -7

So you can see in the picture how long the shaft was as we felt we needed to keep the blades away from the motor. Well in yesterdays cold front we had a lot of wind and the shaft twisted off. So now we have the shaft running through a 4" bearing just before eaching the fan blade. Plus we made a aluminum box to replace the wood. One test in the near future will be placing the motor into a 6" PVC, it fits perfect and will make work on it easier. Also we are going to build a verticle model in the next couple of weeks. Before we tested off we proved we can charge a battery and light a light bulb. In addition we are going to modify one of those wind turbines you find over air vents on roofs. If we replaced the six of those we have with ones turning a motor unstead of just turning and wiring them in phase we should drasticly reduce the battery charge time. Just more playing around. We think if we put one of the roof turbines on a fence post we could charge a cell phone battery, so we will be testing that too. We have a squril cage from a swamp cooler in our junk pile so we are going to mount it verticle and see what it will produce. Today my son cut fins verticle in a five gallon bucket, ran an all thread through the bottom and top and spun it fast enough with a fan to produce 19 V. So we will play with that. If your were nowhere, but had a bucket and the other items needed and could have a portable battery charger from a bucket it might be handy. Not as easy as a store bought charger or a solar charger, but just trying to cover bases with stuff from the junk pile.   |

|